AIRSERVICES France - Propeller workshop and NDT

×

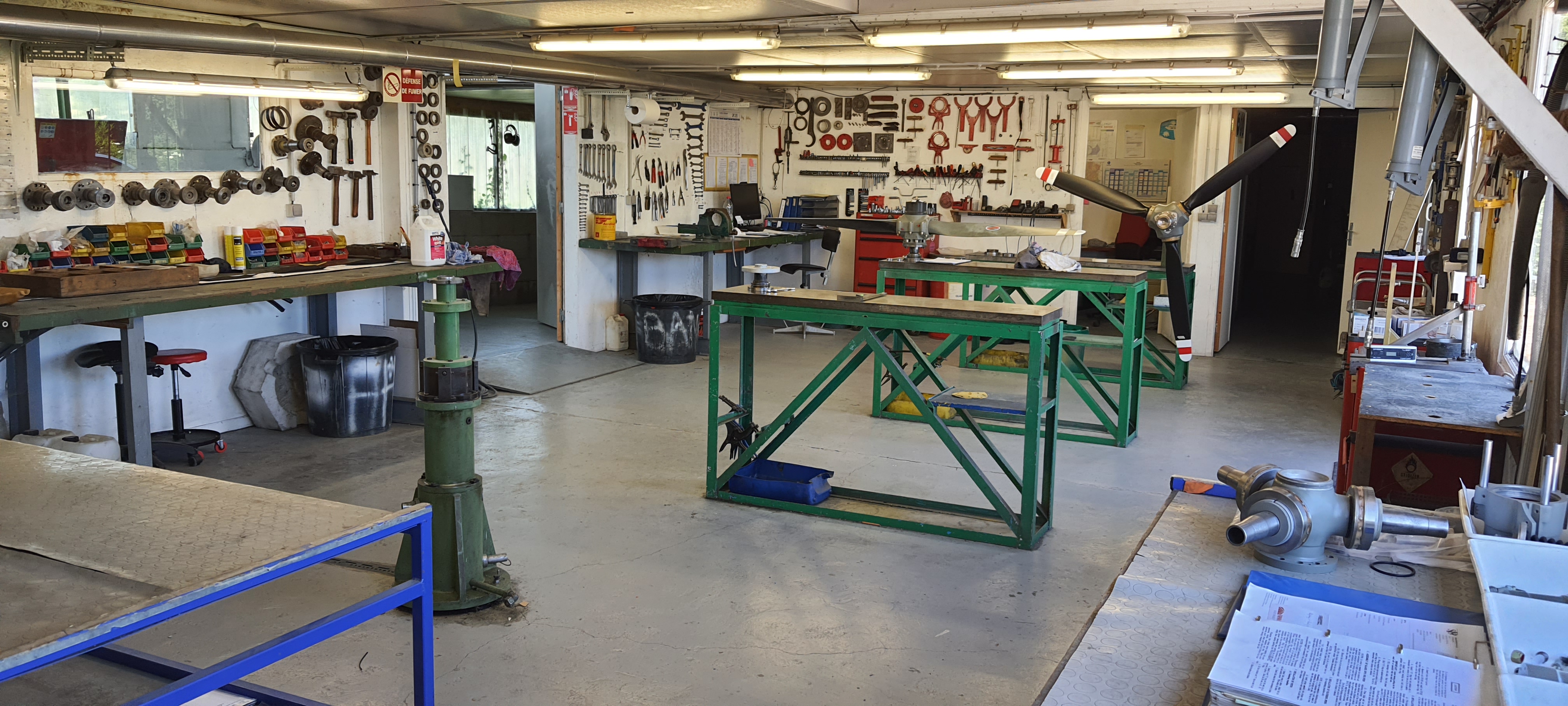

Overhaul • June 15, 2021Propeller Overhaul Workshop

Main room of our workshop, where we measuring and balancing propellers.

© Airservices France

Overhaul • June 18, 2021Four-bladed Propeller of aircraft PC6

Variable pitch propeller which required meticulous adjustments.

© Airservices France

Magnetic Particle Inspection • June 14, 2021Bolt inspection by NDT

The purpose of NDT* is to check that items don't present

any cracks and can be safely used.

© Airservices France

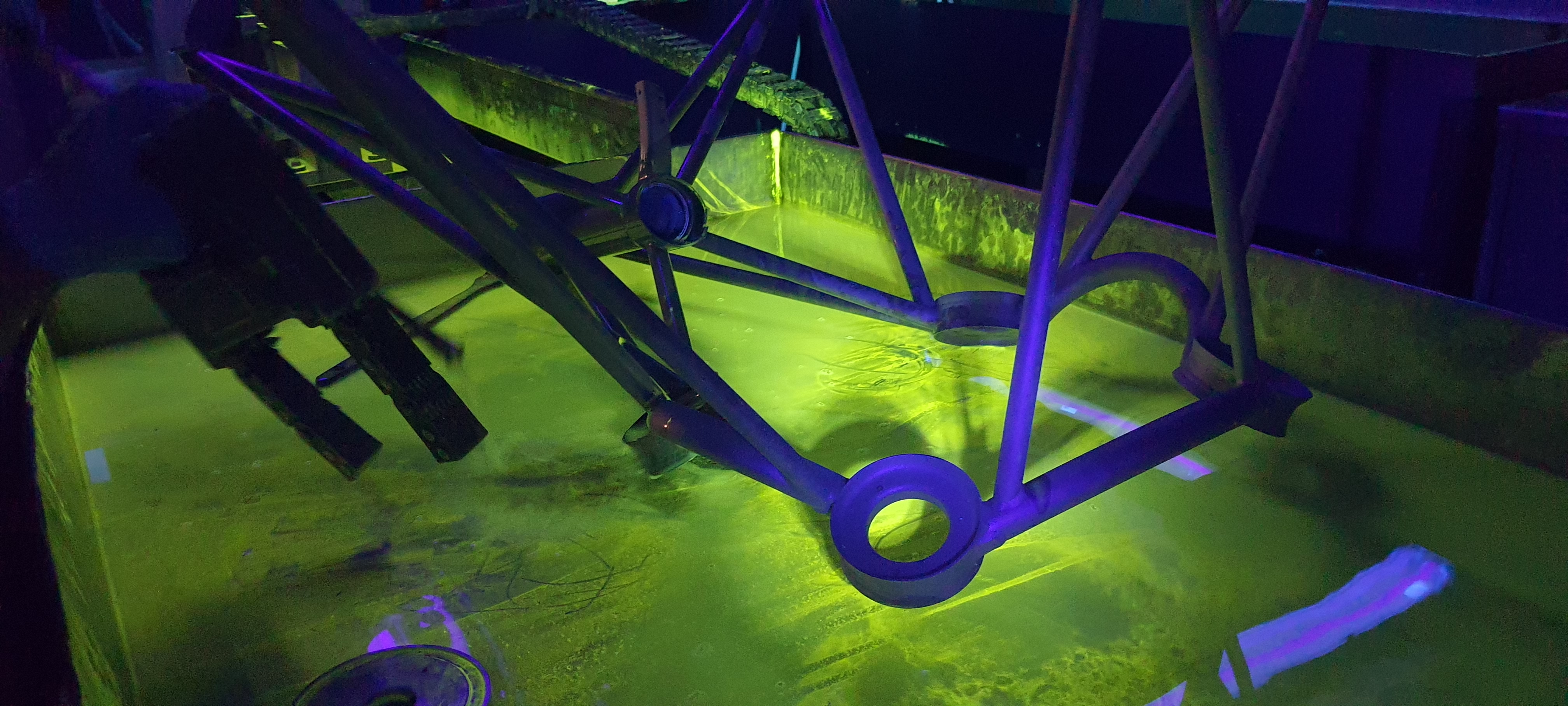

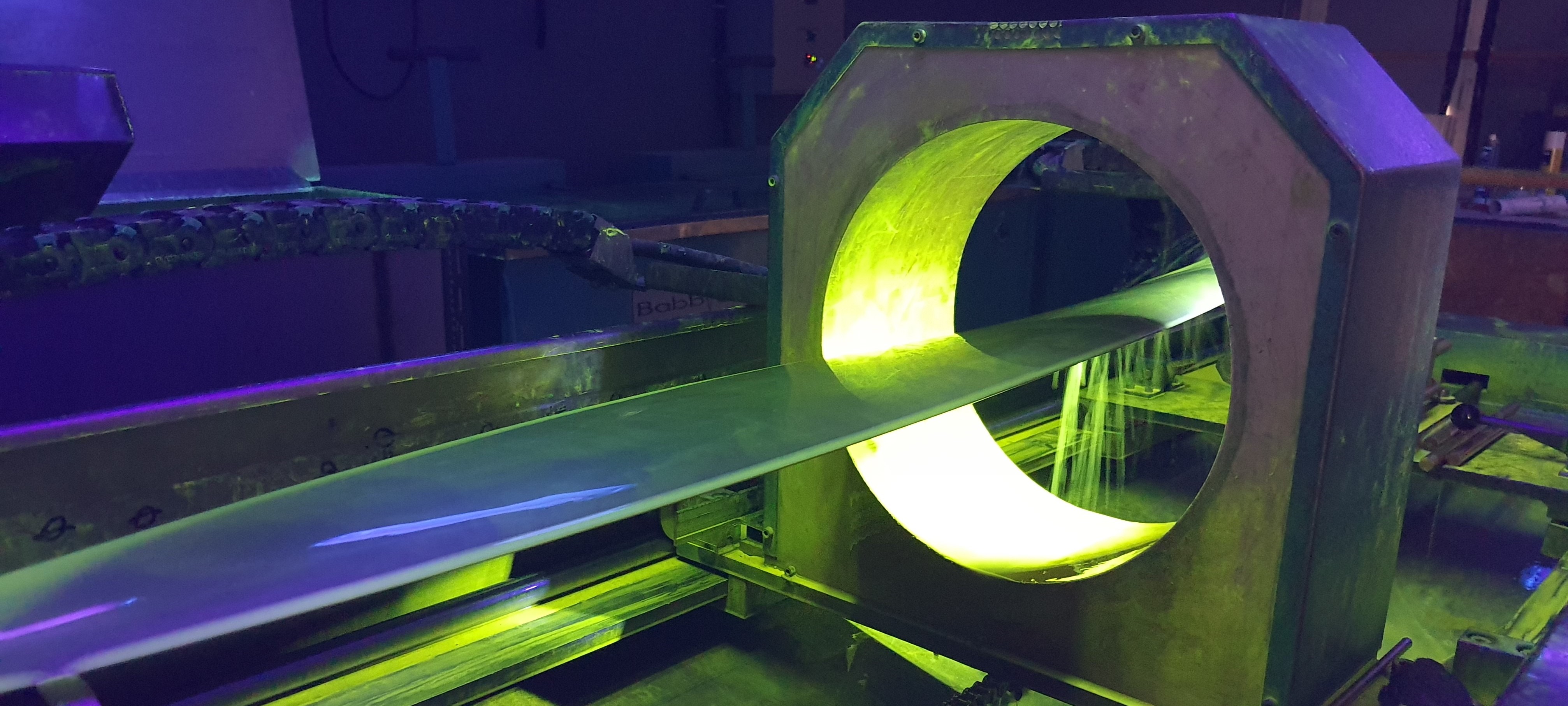

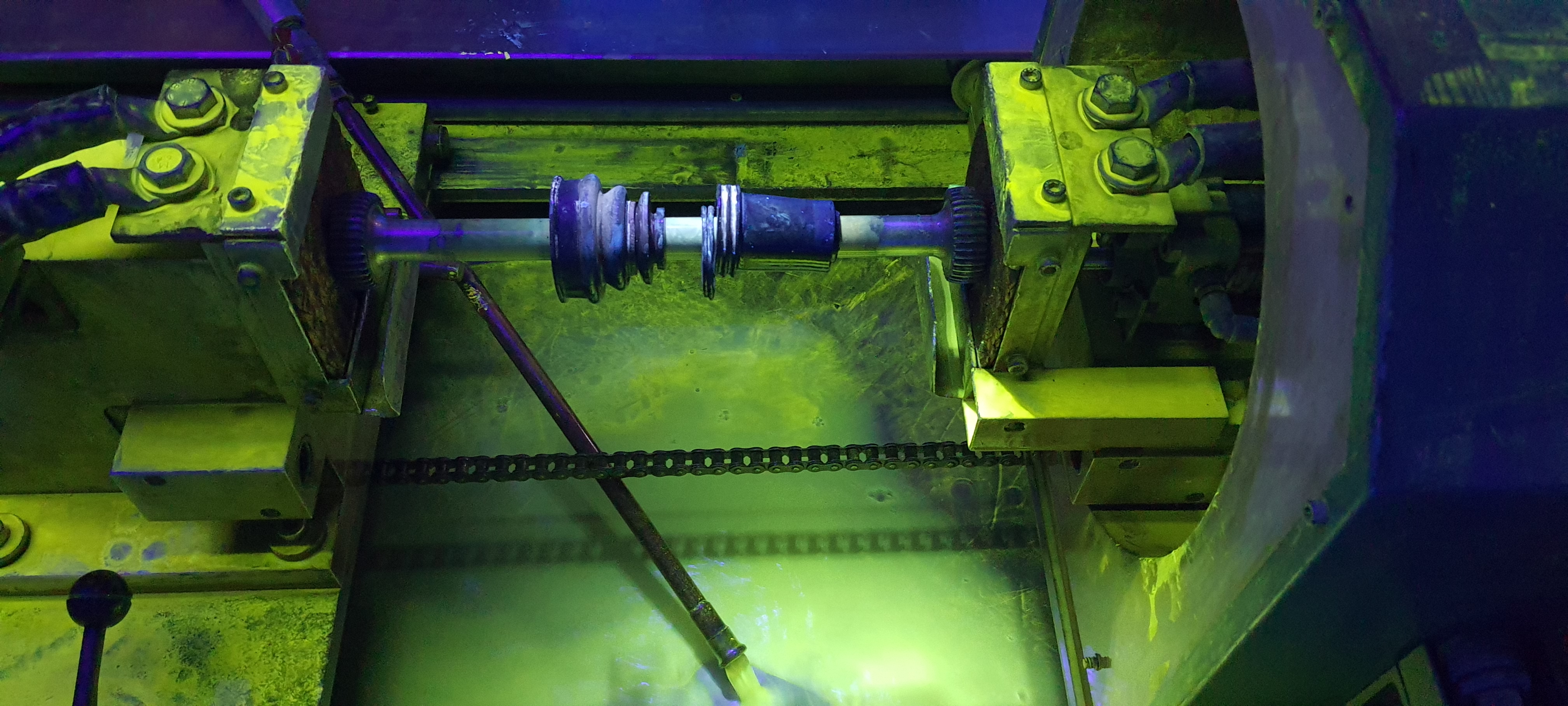

Magnetic Particle Inspection • June 14, 2021Engine mount inspection by NDT

The purpose of NDT* is to check that items don't present

any cracks and can be safely used. Here is the Magnetic Particle Inspection Bench.

© Airservices France

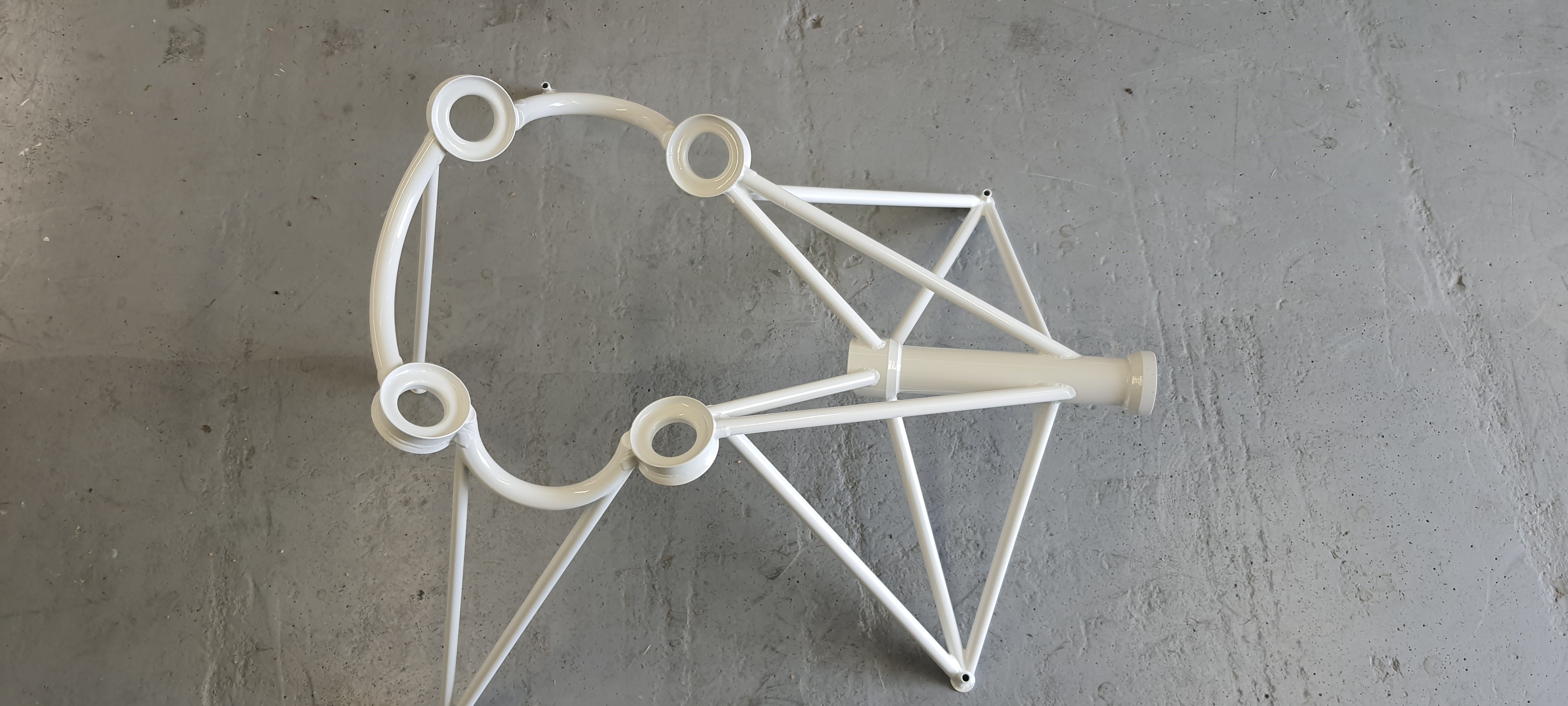

Delivery • June 17, 2021Painted engine mount

Engine mount after being painted and ready to be delivered to the customer.

© Airservices France

Magnetic Particle Inspection • June 14, 2021Engine mount inspection by NDT

The purpose of NDT* is to check that items don't present

any cracks and can be safely used.

© Airservices France

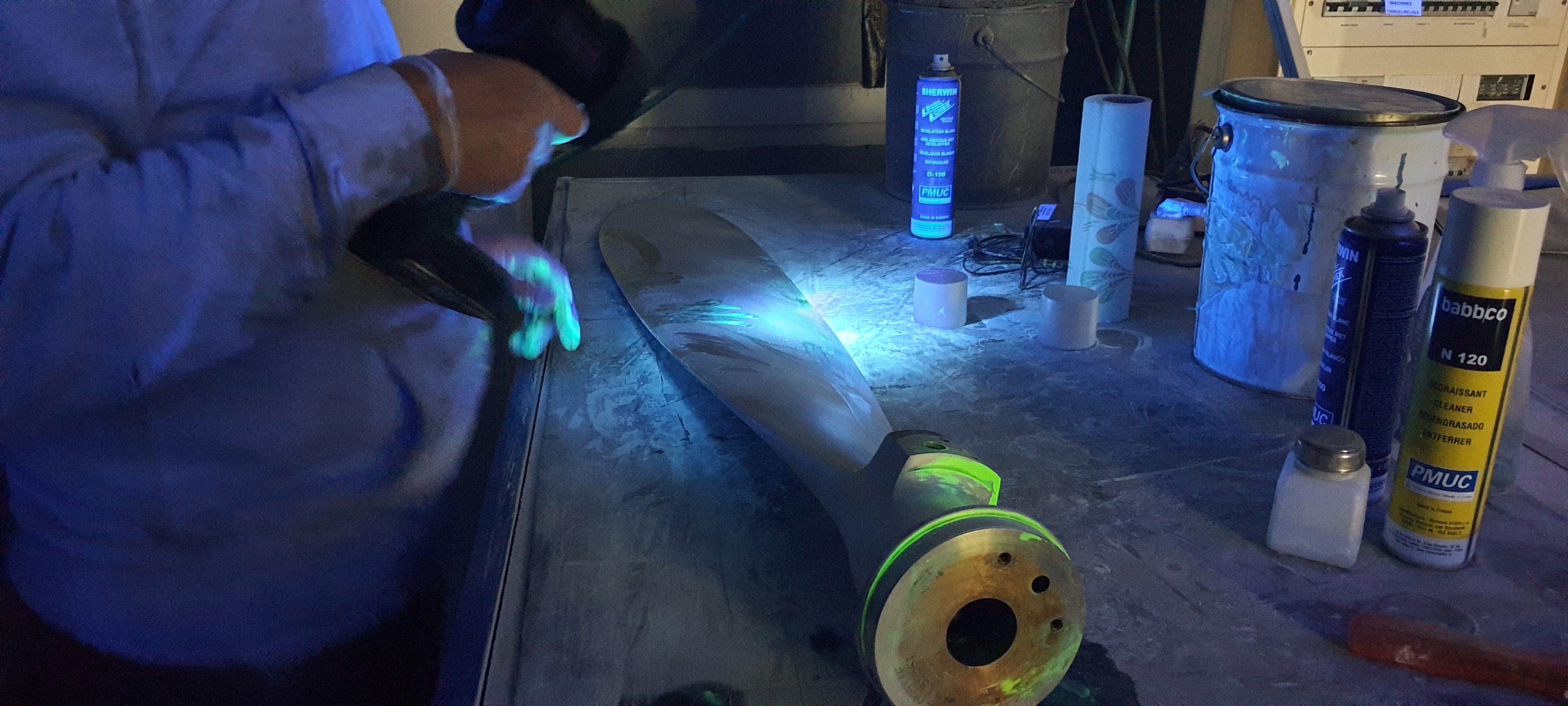

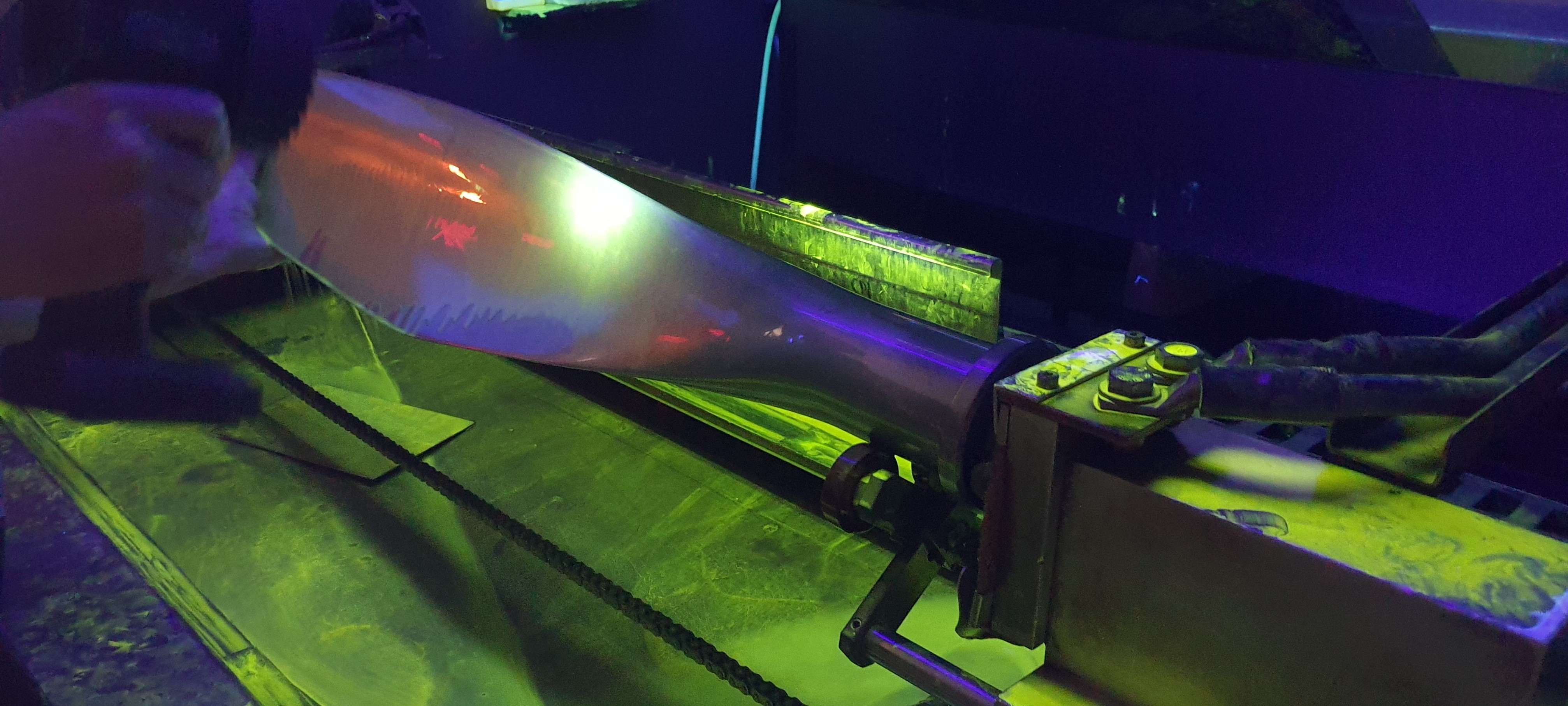

Penetrant Inspection • June 22, 2021Aluminum blade inspection by NDT

The purpose of NDT* is to check that items don't present

any cracks and can be safely used. After painting the blade with a penetrant, UV lampe reveals cracks.

© Airservices France

Sanding • June 17, 2021Blade before sanding

State of an arriving blade which has some imperfections. Our job will be to remove all these

imperfections, nicks, or corrosion.

© Airservices France

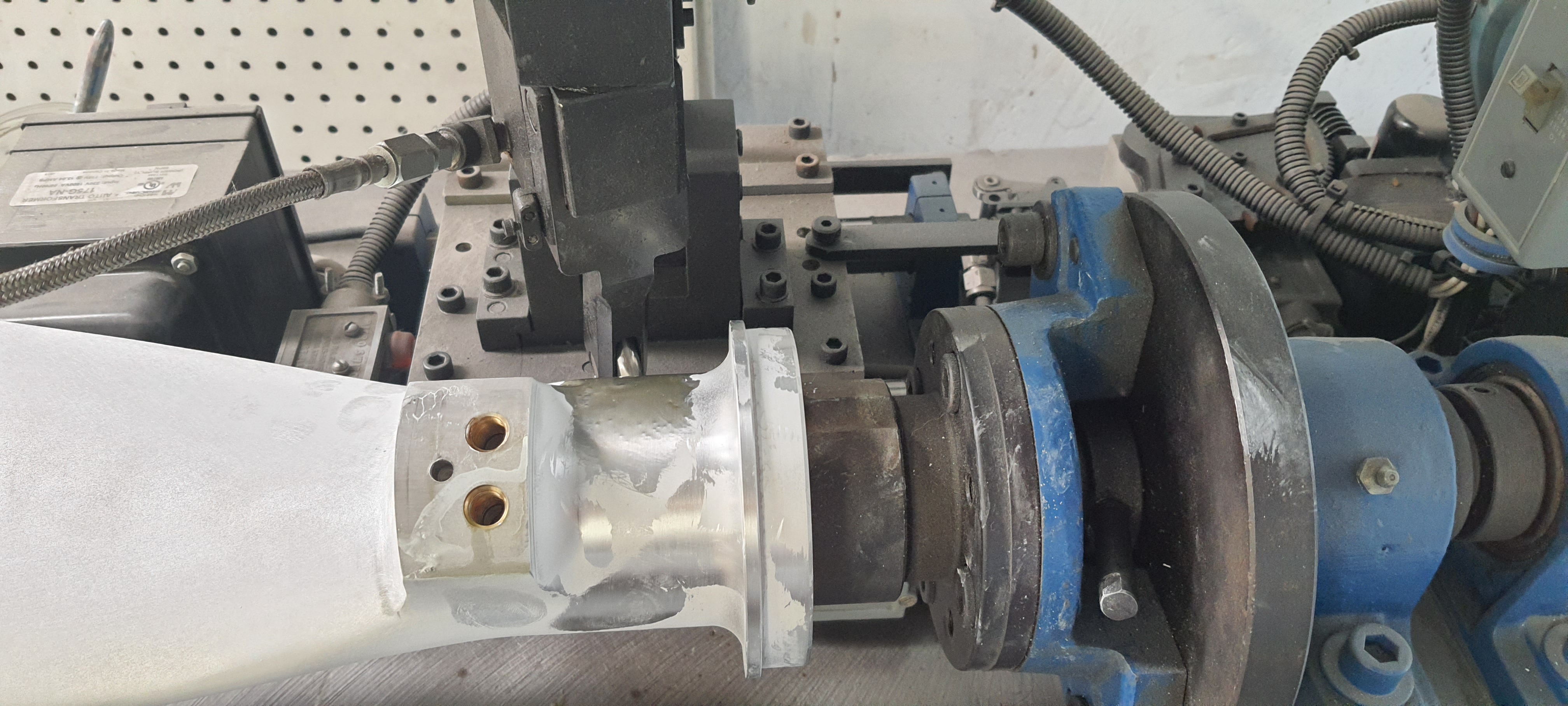

Work Hardening • June 22, 2021Strain hardening of a Hartzell blade

This specific method for Harzell propeller is purposed to reproduce the curved shape (on the propeller hub side).

© Airservices France

Magnetic Particle Inspection • June 14, 2021Demagnetization of an engine mount

After each magnetisation, it is necessary to check that the whole item is demagnetized.

Otherwise, it could create instrumental errors, especially for the compass.

© Airservices France

Manufacturer • July 05, 2021Hartzell Propeller Manufacturer

We are working with several propeller manufacturers including Hartzell, an American manufacturer.

© Airservices France

Manufacturer • June 22, 2021McCauley Propeller Manufacturer

We are working with several propeller manufacturers including McCauley, an American manufacturer.

© Airservices France

Overhaul • June 18, 2021Static balancing of a two-bladed propeller

© Airservices France

Overhaul • June 14, 2021Measuring

First step of the propeller's general overhaul.

© Airservices France

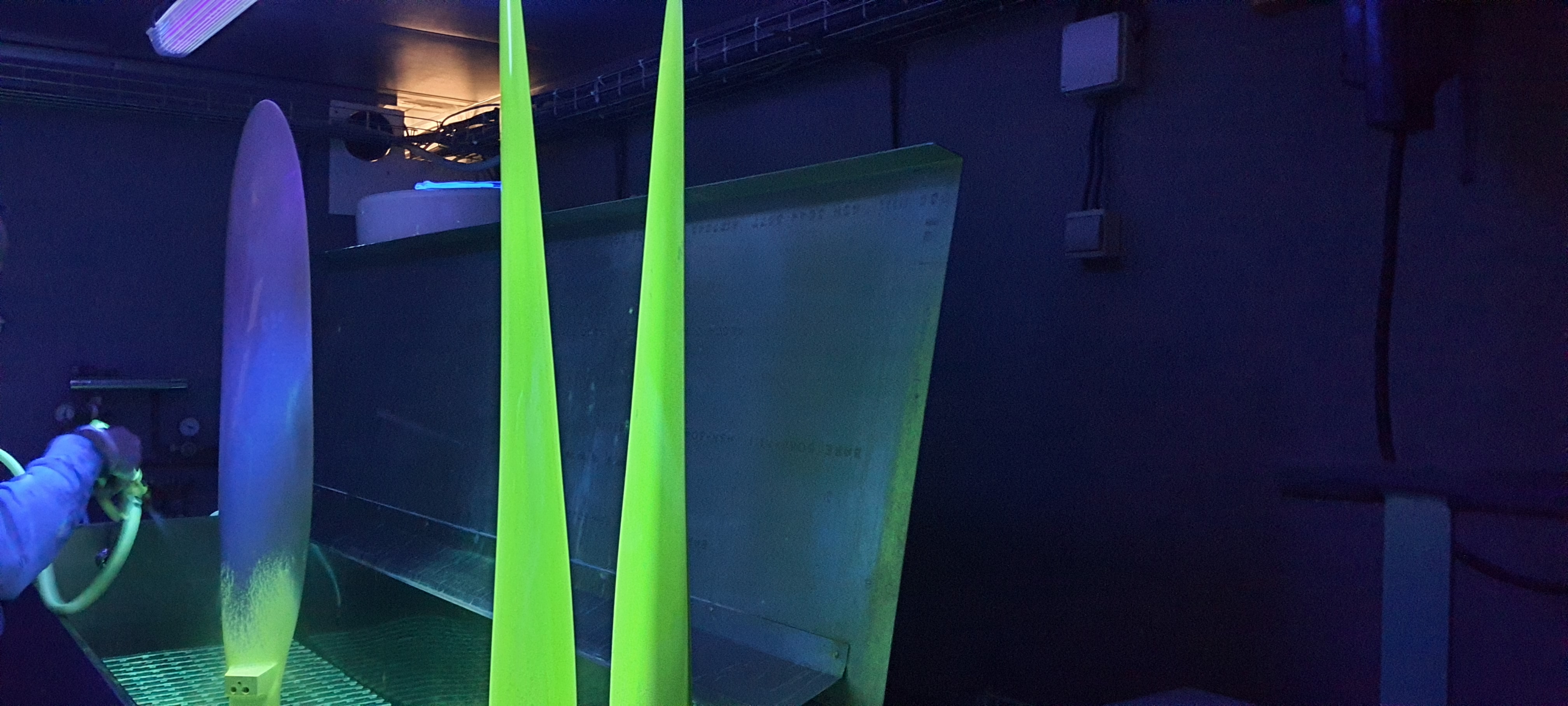

Penetrant Inspection • June 22, 2021Penetrant Application NDT

This penetrant will enable to reveal cracks if there are any.

© Airservices France

Overhaul • June 17, 2021Propeller hub

Propeller hub after being treated with alodine.

© Airservices France

Overhaul • June 18, 2021Three-bladed Propeller

Three-bladed Hartzell Propeller

© Airservices France

Overhaul • June 15, 2021Three-bladed variable pitch Propeller

© Airservices France

Sandblasting • June 14, 2021Sandblasting of an Engine mount

© Airservices France

Manufacturer • June 22, 2021Sensenich Propeller Manufacturer

We are working with several propeller manufacturers including Sensenich, an American manufacturer.

© Airservices France

Painting • June 17, 2021Engine mount painting

© Airservices France

Engine • June 30, 2021Engine's items

These items will be inspected with the Magnetic Particle method to check the lack of cracks.

© Airservices France

Penetrant Inspection • June 22, 2021Penetrant Application NDT

The purpose of NDT* is to check that items don't present

any cracks and can be safely used.

© Airservices France

Magnetic Particle Inspection • June 22, 2021Viewing of a steel blade below UV light NDT

The purpose of NDT* is to check that items don't present

any cracks and can be safely used.

© Airservices France

Painting • June 23, 2021Four-bladed propeller painting

© Airservices France

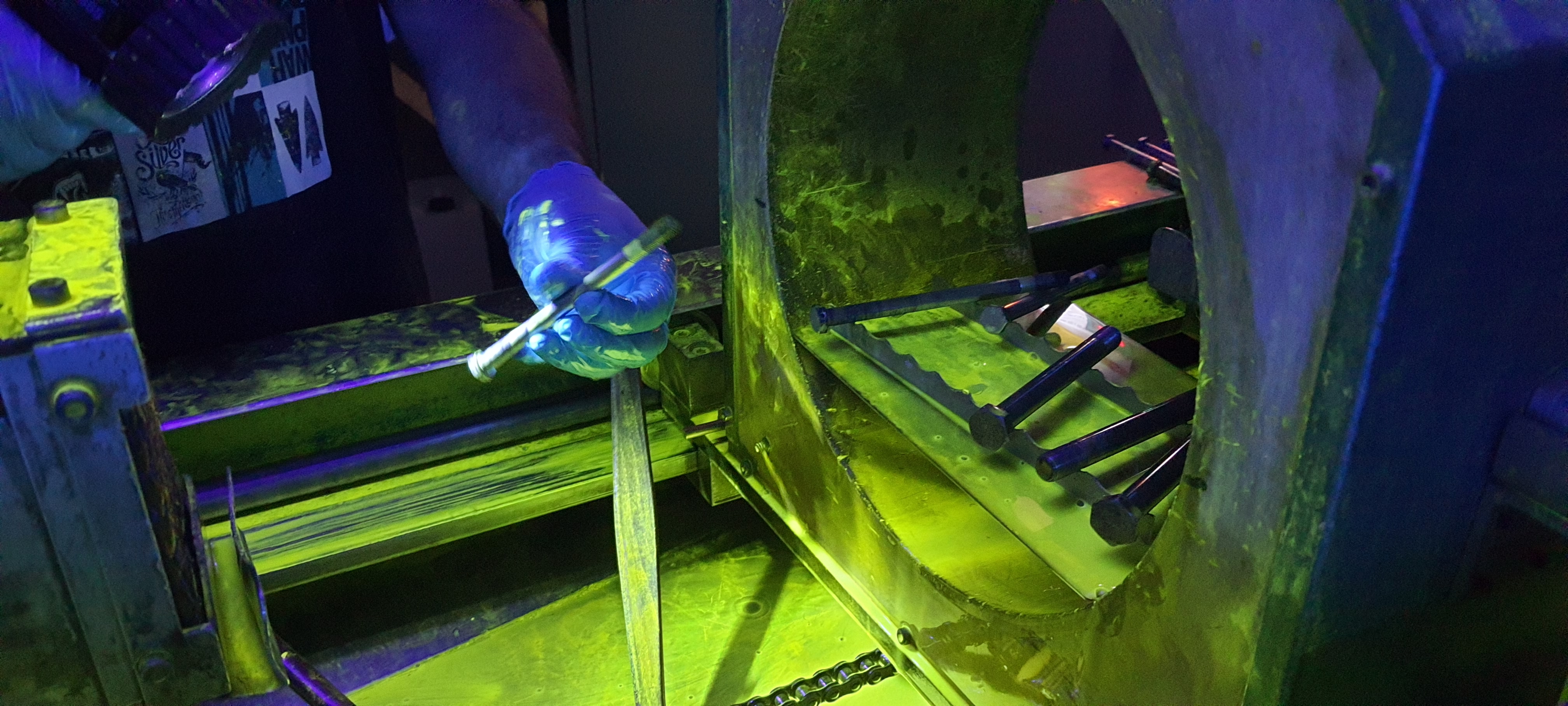

Magnetic Particle Inspection • June 22, 2021Magnetization of a steel blade NDT

The purpose of NDT* is to check that items don't present

any cracks and can be safely used.

© Airservices France

Magnetic Particle Inspection • June 22, 2021Magnetization of a Helicopter item NDT

The purpose of NDT* is to check that items don't present

any cracks and can be safely used.

© Airservices France

Overhaul • June 23, 2021Blade after being treated with alodine

Blade now protected and ready to be painted.

© Airservices France

Intervention • July 13, 2021Eddy Current Probe Calibration

Preparation of the Eddy Current measuring device before intervening.

© Airservices France

Intervention • July 13, 2021Eddy Current Inspection on aircraft PA28

Inspection of boltholes to check if there are free of cracks.

© Airservices France

Intervention • July 13, 2021Viewing of cracks in boltholes with Eddy Current Inspection

Non-Destructive Testing (NDT ) method on an aircraft.

© Airservices France

Intervention • July 13, 2021Aircraft Mechanical Workshop

© Airservices France

❮

❯